We have co-authored a paper in Advanced Functional Materials with the Golovin group from University of Toronto. The team developed a new way to create ultra-repellent omniphobic surfaces that can resist a wide range of liquids—from water to oils—by focusing on the often-overlooked role of the underlying substrate.

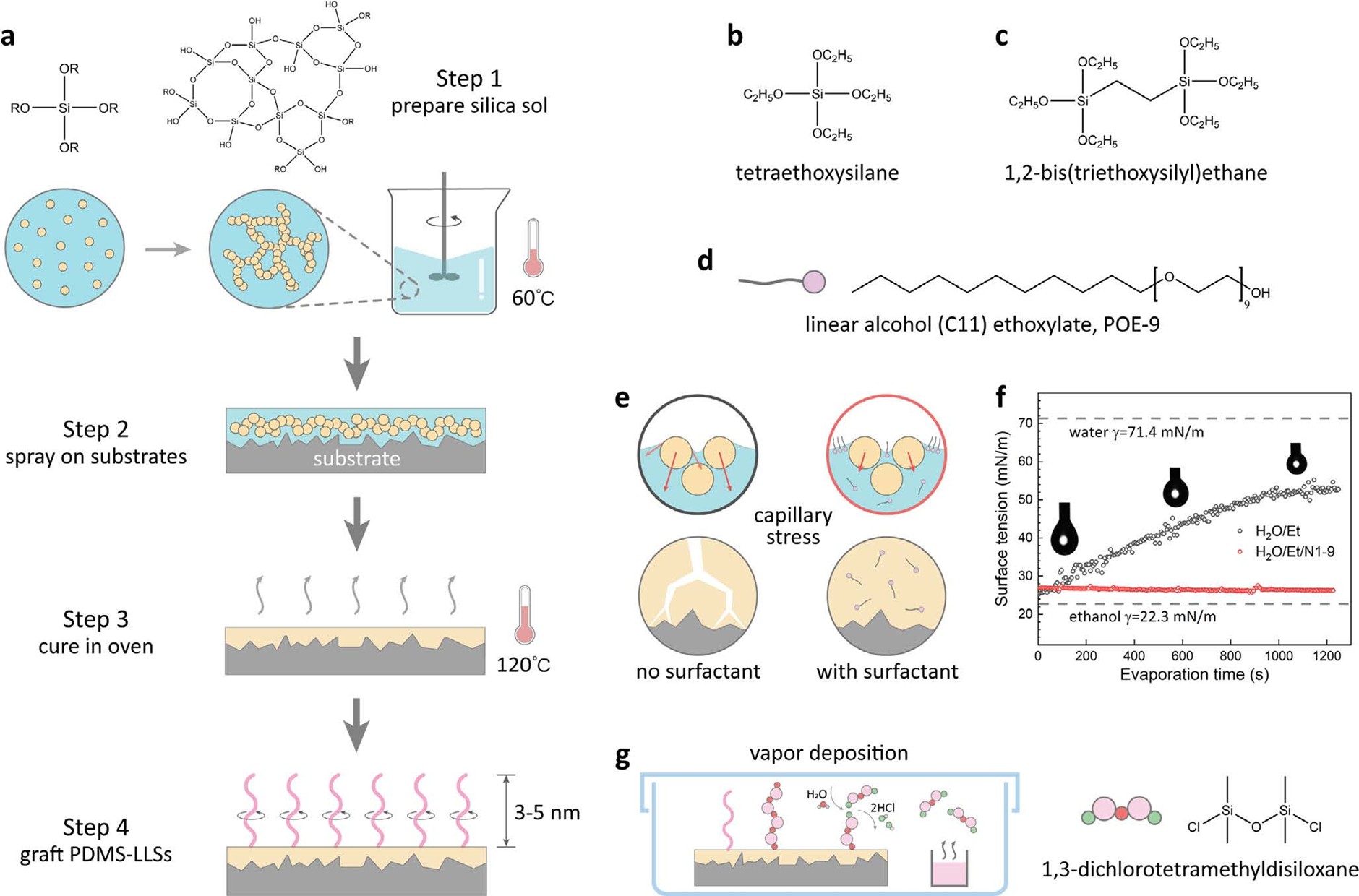

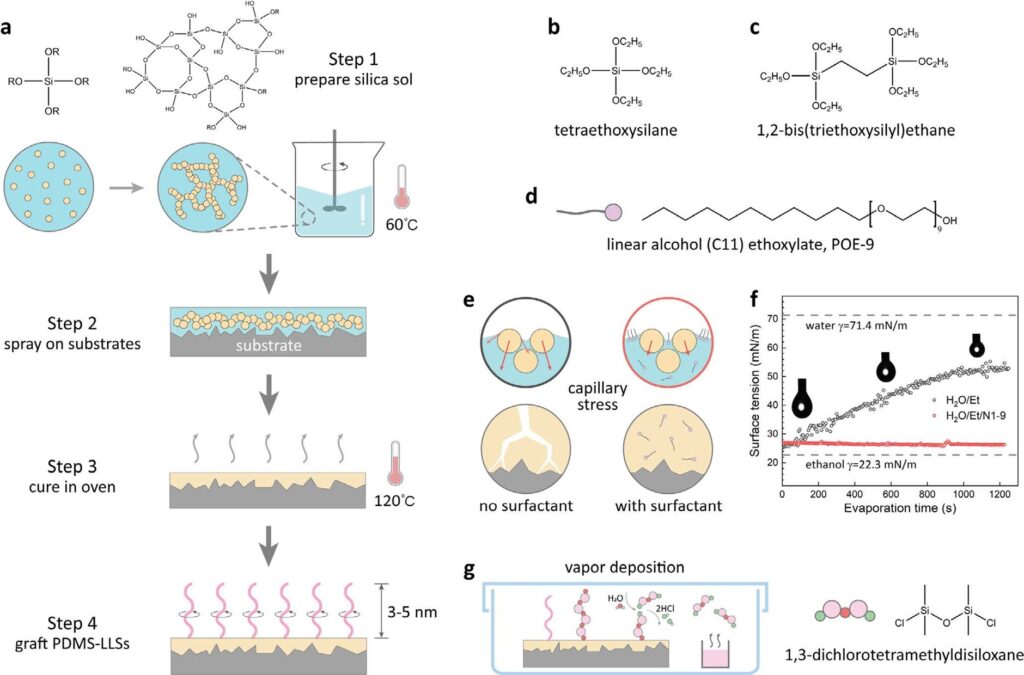

To make these liquid-repelling surfaces, the team used a special silica-based coating combined with a flexible, liquid-like layer made from polydimethylsiloxane (PDMS). This new method smooths out rough surfaces and allows for much thicker, crack-free coatings than previous techniques—up to 100 times thicker.

One key discovery was that the chemical makeup of the surface underneath the coating plays a major role in how well it repels liquids. Specifically, the density of certain chemical groups (called silanols) needs to be high enough to ensure minimal “stickiness” from liquids. By treating the surface with oxygen plasma, we found even challenging liquids like decane and toluene did not stick to the layers.

The team also explored how different substrate materials affect the durability of these coatings. We found two main types of wear: one where the top layer is scratched off, and another where the surface underneath is damaged, which quickly reduces the coating’s effectiveness—especially on softer materials. To solve this, a two-layer system was used using different silica materials, which both smooths the surface and improves durability. This innovation opens the door to applying these advanced coatings on a wider range of materials, making them more practical for real-world use in everything from protective gear to industrial equipment.